Solution

27

2024

-

12

Centralized Heating Project for 46,000 Square Meter District in Jiaxiang County, Shandong Province

The heating season in most areas is beginning to draw to a close with the arrival of March. In this heating season, air heating operation and energy consumption, I believe that these issues have been the focus of market concern. Below, we will focus on a centralized heating renovation case in Jining, Shandong Province for analysis. This project started in October 2019, began formal operation on November 26, and as of February 29, 2020, it ran for 95 days, with a total power consumption of 974,510 degrees.

The heating season in most areas is beginning to draw to a close with the arrival of March. In this heating season, air heating operation and energy consumption, I believe that these issues have been the focus of market concern. Below, we will focus on a centralized heating renovation case in Jining, Shandong Province for analysis. This project started in October 2019, began formal operation on November 26, and as of February 29, 2020, it ran for 95 days, with a total power consumption of 974,510 degrees.

I. Project situation

1. Construction

The project is located in Huanggang Village, Jiaxiang County, Jining City, Shandong Province, which is a relatively old neighborhood. The construction area of the district reaches more than 46,000 square meters, a total of 13 buildings, each building has 6 floors, 1 floor height of 4 meters, is the household's miscellaneous room; 2 to 6 floors 3 meters high, for the residence of the residents. The building is not insulated, and the neighborhood is more open, with greater heat dissipation, and the brick wall structure is a two-four wall.

2. Climate

The average temperature of the coldest month in Jining City in the past winter was 0℃, and the lowest temperature was -15℃. The case is located in the area around the open, windy, the temperature will be slightly lower. And the current heating time, the outdoor temperature range of 1 ℃ ~ 5 ℃.

3. System situation

The project is equipped with 17 sets of 50P Meiken low-temperature make-up air-energy heat pump units. When the outlet water temperature of a single unit is 50℃ and the return water temperature is 45℃, the heating capacity can reach 104kW.

Considering the cost of transformation and time cost, comprehensive views of all parties, it was decided to follow the original form of heating end - radiant form of floor heating, but the aging pipeline and the original boiler heating mains were replaced, and the size and direction of the buried mains were redesigned.

System through the controller plus pump station equipment, the end of the water temperature control, to achieve the system heat supply on demand, so that better avoid waste, reduce system energy consumption, to achieve the purpose of energy saving.

II. Operational situation

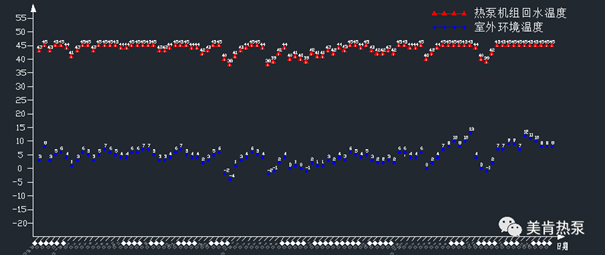

In mid-November, the project transformation was completed and debugging was completed, on November 26th formal operation. During operation, the ambient temperature is 1℃~5℃, the return water temperature of the unit is 40℃~45℃ (40℃ return water when the weather is cold, and adjusted to 45℃ when the temperature is high), and the indoor temperature is basically kept above 20℃. As of February 29, the system has been running for a total of 95 days, with a total power consumption of 974,510 degrees. The average daily power consumption is 10258 degrees, the average daily power consumption per square meter is 0.223 degrees.

III. Summary

1. From the data, as of February 29th, the total running time in November was 5 days, with a total consumption of 51,545 kWh, an average of 10,309 kWh per day, and an average of 0.222 kWh per square meter per day; the total running time in December was 31 days, with a total consumption of 325,686 kWh, an average of 10,506 kWh per day, and an average of 0.227 kWh per square meter per day; the total running time in January was 31 days, with a total consumption of 97,510 kWh, an average of 10,258 kWh, and an average of 0.223 kWh per square meter per day. In January, a total of 31 days of operation, the total power consumption of 331,046 degrees, the average daily power consumption of 10,679 degrees, an average of 0.23 degrees per square meter per day; February, a total of 28 days of operation, a total of 266,233 degrees, an average of 9,509 degrees of power consumption per day, an average of 0.205 degrees per square meter per day. It can be seen that the power consumption of air energy heating is very much related to the temperature, the lowest temperature in January, the average energy consumption is the highest.

2. During the operation period, the air energy mainframe operated well, and the indoor temperature was maintained at a stable level of about 20°C. The average daily power consumption was 10,258 degrees. The average daily power consumption is 10,258 degrees, compared with similar products on the market, the operating energy consumption is much lower. Both environmental protection and energy saving, under the trend of banning coal, air energy is a very suitable choice to replace coal-fired boilers.

Keyword: Full DC Inverter Heat Pump

Get a Free Quote

We welcome you for any inquiries,tell us about your project to receive a no-obligation price quote

Hotline

Address

Building 4,No.7,Xinhui Road,Wusha Community,Daliang Town,Shunde District,Foshan City,Guangdong Province,China

Follow Us